Techma

Gebrauchte Erodiermaschinen

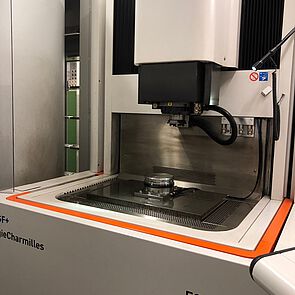

Sie sind auf der Suche nach einer gebrauchten Erodiermaschine? Mit TECHMA sind Sie auf der sicheren Seite. Die Kooperation mit GF Machining Solutions sowie über 25 Jahre Erfahrung garantieren erstklassige Qualität und Betreuung. Von der gewissenhaften Grundreinigung bis zur abschließenden Funktionsprüfung: Die fachkundige Reparatur und sorgfältige Wartung gebrauchter Erodiermaschinen durch unsere Experten sorgt nicht nur für einen langlebigen und zuverlässigen Betrieb in diversen Anwendungsbereichen; sie gewährleistet ebenso eine in diesem Rahmen einzigartige Werksgarantie.

TECHMA - GEBRAUCHTMASCHINEN MIT GARANTIE

TECHMA ist der einzige Anbieter, bei dem Sie auf gebrauchte Erodiermaschinen eine Werksgarantie erhalten. Mit einem Team von über 20 Fachleuten aus Beratung und Betreuung sowie einem weltweiten Liefer- und Montage- Service, sichert TECHMA eine schnelle und professionelle Abwicklung Ihres Auftrags zu.

SOFORTKONTAKT: +49 (0)7022 94335-0 oder info@techma.de

SERVICE

Um unseren Kunden dauerhaft als kompetenter Partner zur Seite stehen zu können, optimieren wir unsere Serviceleistungen kontinuierlich. Das TECHMA-Team aus kompetenten Spezialisten verfügt über langjährige Erfahrung in der Überholung, Diagnose, Wartung und Reparatur von Erodiermaschinen der Marken AGIE und Charmilles. Profitieren Sie von unserem breit gefächerten Serviceportfolio sowie einer großen Auswahl sowohl neuer als auch gebrauchter Ersatzteile.

Versierte Servicetechniker und Monteure sorgen für eine professionelle Montage und Inbetriebnahme in Ihrem Unternehmen.

![]()

Ihre Erodiermaschine läuft nicht mehr rund? Wir stehen Ihnen kurzfristig zur Verfügung und finden für nahezu jedes Problem eine Lösung.

![]()

SCHULUNG

Ob Einsteiger oder Profi, ob Inbetriebnahme oder Programmierung – TECHMA bringt Ihr Unternehmen auf den neuesten Stand.